If the bend radius is in the range of about 3 to 10 times the sheet thickness it is reasonable in an approximate analysis to consider the material as rigid perfectly plastic as discussed in section 6 5 2.

Moment bending sheet metal plastic.

I have foung that simle carpeners square will damn close 90 degree.

The plastic bending of a sheet metal having tension compression asymmetry was investigated in this work with az31b mg sheets particularly focused on its deformation behavior.

10 4 bending a rigid perfectly plastic sheet under tension.

It is the maximum stress that the cross section is subjected to when the load is applied between the two points of the specimen.

Slip the kevlar on and position the assebly on your choice of straight surfaces energize place plastic on element and wait till bercomes taffy like and make your bend.

The sheet metal bending also called press brake bending it is a process of plastic deformation of the work over an axis creating a change in the parts geometry like a v shape.

You can see this in the fogging of some clear plastics on the outside surface.

When a bend is made in sheet metal or plastic the outside of the material structure expands while the inside compresses.

All this occurs on a molecular level.

The cross section will not yield linearly through the section.

N mm2 or mpa the symbol is σb.

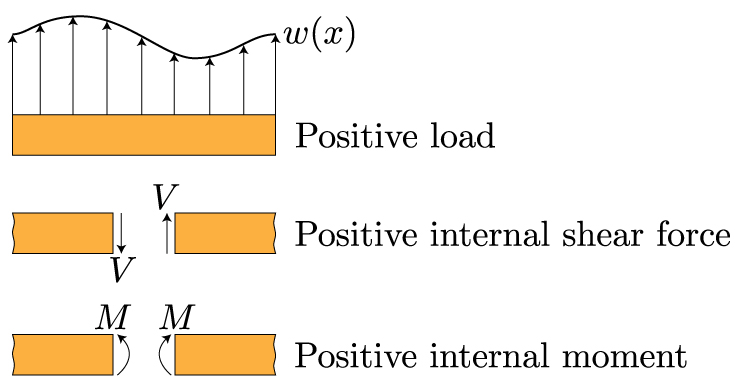

Plastic bending begins when an applied moment causes the outside fibers of a cross section to exceed the material s yield strength.

First experiment with a few scraps to get the time and heat right.

Use long thin 1 inch or so in width test strips to practice your technique and learn how your particular heat source affects your chosen thickness of plastic.

Set up plastic or acrylic sheet in a simple bending jig.

Also we neglect through thickness stress and assume plane strain bending.

For very small radius bends these assumptions may not be justified.

Sheet metal bending is the plastic deformation of the work over an axis creating a change in the part s geometry.

Loaded only by a moment the peak bending stresses occurs at the outside fibers of a cross section.

U shape or channel shape along a straight axis in ductile materials.

To set up your plastic or acrylic sheet to bend simple curves for your miniature and model projects you need to first remove the protective covering from the material you wish to bend.

It is one of the indexes of metal strength.

It is the maximum stress that the sheet metal material is subjected to before pulling out.